Ford to invest $2B in universal EV platform, 'assembly tree' to build cheaper EV trucks

Published in Automotive News

LOUISVILLE, Kentucky — Ford Motor Co. on Monday said it will invest $2 billion in Louisville Assembly Plant here to build the first vehicle — a midsize truck — on its Universal EV Platform using a new manufacturing "assembly tree" more than a century after the invention of the moving assembly line.

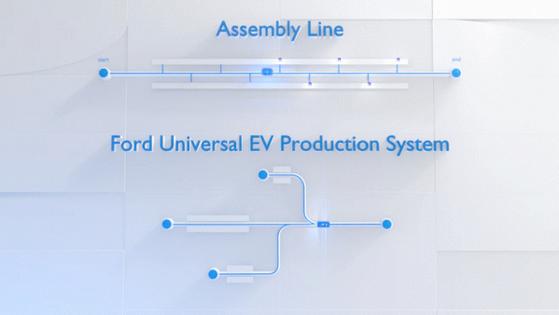

It's a "Model T moment" for the Dearborn automaker, CEO Jim Farley has said, as the Blue Oval confronts a bumpier-than-expected adoption of electric vehicles, particularly in the United States, and increasing concerns about global competition, particularly from China. Sharing a platform with multiple "top hats" for trucks, SUVs and crossovers — and installing the new Ford Universal EV Production System that features three sub-assemblies in which the front and rear of vehicles are assembled separately — are meant to increase efficiency, improve on quality and save on costs.

“We have all lived through far too many ‘good college tries’ by Detroit automakers to make affordable vehicles that ends up with idled plants, layoffs and uncertainty," Farley said in a statement. "So, this had to be a strong, sustainable and profitable business. From Day 1, we knew there was no incremental path to success. We tore up the moving assembly line concept and designed a better one."

This all comes as growth of EV sales has slowed in the United States. The Trump administration also has taken actions to dismantle greenhouse gas emission regulations and consumer EV incentives that he has characterized as an "EV mandate."

Ford already has canceled an EV program for a larger, three-row SUV, and has delayed to 2028 production of its next-generation electric commercial van and pickup truck. The midsize, four-door pickup truck similar in exterior size to the Ford Maverick will launch in 2027 for the United States and export markets and is expected to start around $30,000 ― addressing a "horribly underserved" market under $40,000, said Jim Baumbuck, vice president of advanced product development, cycle planning and programs.

With the start of the transition of Louisville Assembly at the end of the year, Ford Escape and Lincoln Corsair production will end, though vehicles are expected to be available into 2026. The investment secures 2,200 hourly jobs. Louisville Assembly as of April 2024 employed more than 3,000 hourly workers, according to Ford's website.

The Ford Universal EV Platform is a simplified product of the California-based EV hardware and software "skunkworks" team that executives have emphasized for months will be revolutionary. More than 500 engineers are working out of Ford's new Long Beach development center. The company emphasized the work of 122 years of experience and the mentality of a Silicon Valley startup.

“We took a radical approach to a very hard challenge: Create affordable vehicles that delight customers in every way that matters — design, innovation, flexibility, space, driving pleasure, and cost of ownership — and do it with American workers,” Farley said.

Meanwhile, the Ford Universal EV Production System incorporates an assembly tree with three sub-assemblies that eventually combine instead of the one long conveyor that has been the hallmark of mass vehicle assembly since Henry Ford introduced it at the Highland Park plant in 1913 for Model T, a vehicle that could be owned by the masses.

Large, single-piece aluminum unicastings replace dozens of smaller parts, so that the front and rear of the vehicle can be assembled separately. They then combine with the structural battery, which is assembled independently with seats, consoles and carpeting.

The midsize truck will use batteries from the $3 billion BlueOval Battery Park Michigan in Marshall that is expected to begin production next year. The plant will produce lithium-iron-phosphate batteries, which don't use cobalt or nickel, making them less expensive than traditional EV batteries. They also are less likely to catch fire, though less energy dense.

In a move that's drawn scrutiny, Ford is licensing technology from Chinese battery maker Contemporary Amperex Technology Co. Ltd. to produce the batteries in the United States rather than importing them from China. Crosstown rival General Motors Co. plans to import LFP batteries from CATL in China for the Chevrolet Bolt until LFP production with its South Korean partner, LG Energy Solution, begins in Tennessee in 2027.

The EV platform reduces parts by 20% compared to a "typical vehicle," with 25% fewer fasteners, 40% fewer workstations dock-to-dock in the plant and 15% faster assembly time, Ford said. The wiring harness is 4,000 feet shorter than the Mustang Mach-E's and much lighter.

The company characterized the platform as having a lower cost of ownership over five years than a 3-year-old used Tesla Model Y. Farley has said the platform will have a "handful" of top hats to support multiple models. A video in a media press kit shows seven top hats, though Ford says it's too early to say exactly how many models the platform will support.

Ford described the midsize truck as having more passenger room than the latest Toyota RAV4, even before including the frunk and the truck bed. The RAV4 has a total passenger volume of 98.9 cubic feet. Ford expects a 0-60 mph time on the truck to be as fast as the Mustang EcoBoost with more downforce.

Further details on the midsize truck, including its reveal date, exact starting price, battery range and charge times will be shared later, Ford said.

The Louisville investment will secure 2,200 hourly jobs. The Kentucky Economic Development Finance Authority is supporting the project. Ford will expand the plant by 52,000 square feet and upgrade the digital infrastructure for more quality scans.

“This announcement not only represents one of the largest investments on record in our state," Kentucky Gov. Andy Beshear said in a statement, "it also boosts Kentucky’s position at the center of EV-related innovation and solidifies Louisville Assembly Plant as an important part of Ford’s future."

In the new assembly tree, parts travel to line workers in a kit. All fasteners, scanners and power tools are there to use, reducing twisting, reaching and bending for workers. Assembly could be 40% faster compared to the vehicle currently built in Louisville. Some of that time, however, will be reinvested into insourcing and automation, ultimately netting a 15% speed improvement, Ford said.

Quality has been a large focus at Ford over the past few years. The company last month disclosed a single recall is costing it $570 million, contributing to a second-quarter earnings loss. The Blue Oval in 2025 already has set a record for recalls in a single year from any automaker, though details show improvement for its newest model years.

Kentucky is significant for Ford. In addition to Louisville Assembly, Kentucky Truck Plant is home to the Super Duty pickup as well as the Ford Expedition and Lincoln Navigator, making it the company's most profitable plant. In 2021, Ford also announced a $5.8 billion investment with Korean battery partner SK On Ltd. for two EV battery plants. The first is set to begin production this year, while the other has been delayed.

©2025 www.detroitnews.com. Visit at detroitnews.com. Distributed by Tribune Content Agency, LLC.

Comments